01

Track air conditioning

Used for straddle/hanging monorail and high/medium and low speed maglev trains in various cities

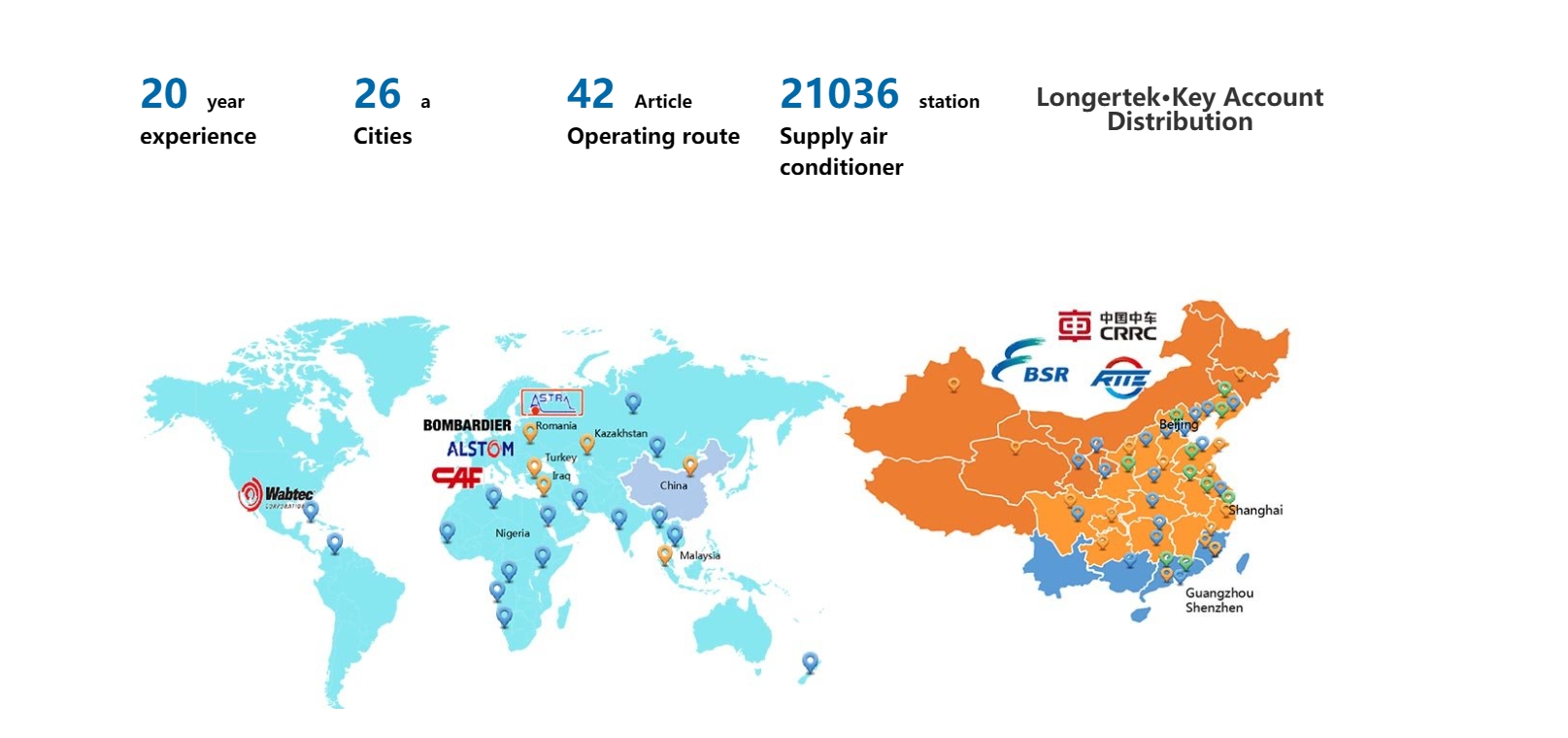

Shandong Langjin Technology Co., Ltd. was established in 2000. The company was listed on the Shenzhen Stock Exchange's Growth Enterprise Market in June 2019 with the stock code: 300594, a registered capital of 89.9817 million yuan, and more than 800 employees. It has Qingdao Langjin Technology Co., Ltd., Qingdao Ruiqing Software Co., Ltd., Shenyang Langjin Technology Co., Ltd., Suzhou Langjin Rail Transit Equipment Co., Ltd., Guangdong Langjin Rail Transit Equipment Co., Ltd., Foshan Langjin Rail Transit Equipment Co., Ltd., Shenzhen Langjin Rail Transit Equipment Co., Ltd., etc.

Langjin Technology adheres to the corporate culture philosophy of "Virtue, Benefit and Wisdom" and the business philosophy of "Made by Langjin = Made with Heart"; is committed to the energy-saving research of rail transit vehicles; and focuses on the design and manufacture of energy-saving vehicle air conditioners.

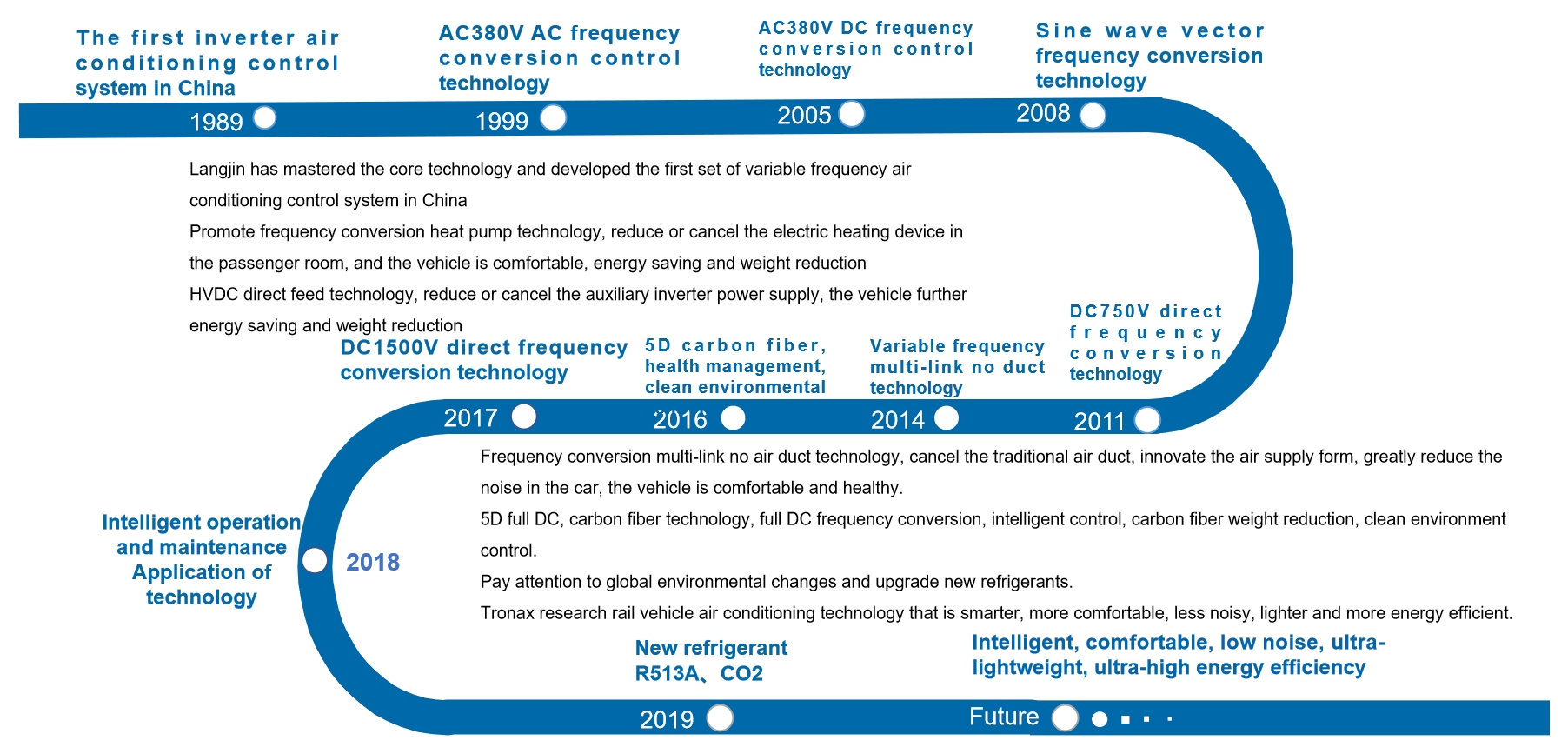

Langjin Technology was the first to introduce variable frequency heat pump technology into the vehicle air conditioning industry; completed energy-saving comparative tests of air conditioning technology in more than eight regions; the company was selected by the National Development and Reform Commission for three consecutive years in 2015, 2016 and 2017…

Used for straddle/hanging monorail and high/medium and low speed maglev trains in various cities

DC variable frequency compressor, low noise, vehicle-specific inverter with high reliability

Multiple systems in one vehicle, healthy, comfortable, smart and energy-saving

Air-cooled variable frequency high energy efficiency ratio, safe and reliable, large air volume, large screen, all Chinese

Applicable to 5G communication base stations, power industry, and outdoor cabinets of environmental monitoring stations

A fully DC variable frequency rail transit vehicle air conditioning unit, the condensing fan, ventilator and compressor are all driven by permanent magnet synchronous motors, with high efficiency and stepless speed regulation, which can adjust the compressor speed and air volume in real time according to load demand

Through temperature, humidity, pressure, passenger flow, air volume and other parameters, logical operations and control systems are performed according to human comfort, greatly improving comfort.

Heat pump heating uses the reverse Carnot cycle principle, absorbing heat from a low-temperature heat source (outside the car) and supplying heat to a high-temperature heat source (inside the car). The amount of heat supplied to the interior is equal to the heat absorbed from the outside plus the energy input by the compressor.

Automatically find the maximum cooling or heating capacity under ambient temperature, load and other parameters to avoid repeated start and stop of the compressor affecting passenger comfort and avoiding damage to the compressor

The DC power input range can be increased, and DC500V~DC900V can meet the requirements, which expands the use range of DC-powered air-conditioning units. At the same time, frequency conversion control of various components of the air-conditioning unit is realized to achieve energy saving of the whole vehicle.

The air conditioning unit and the control cabinet are integrated into one assembly. The internal components and electronic control components of the unit adopt modular design, which is simple and reliable to disassemble and assemble, and convenient for maintenance.